Metalworking Projects

Our project team has gained extensive expertise in the design and execution of comprehensive metalworking projects.

Our project team has gained extensive expertise in the design and execution of comprehensive metalworking projects.

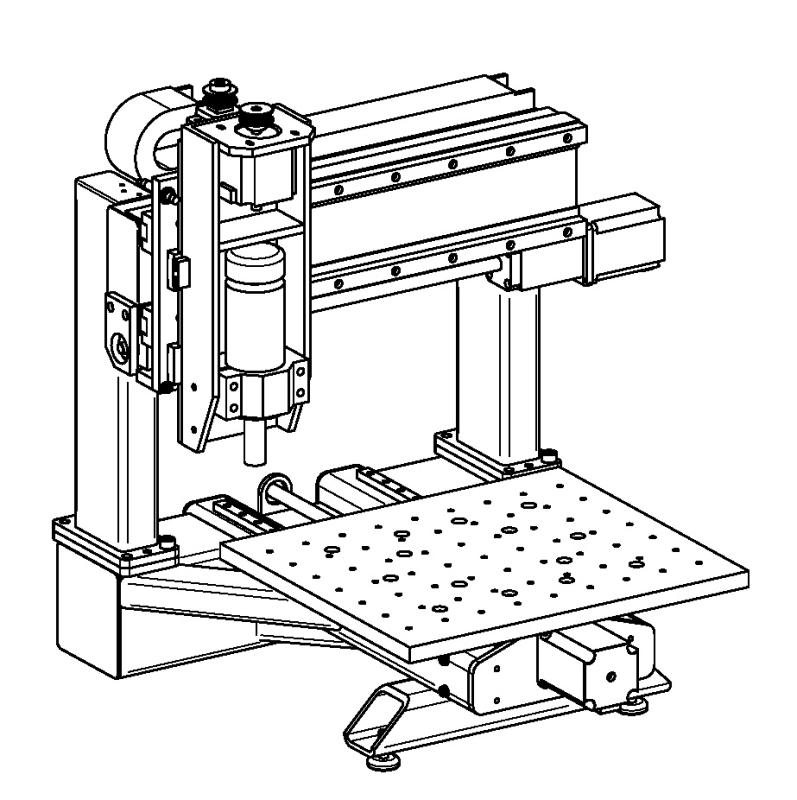

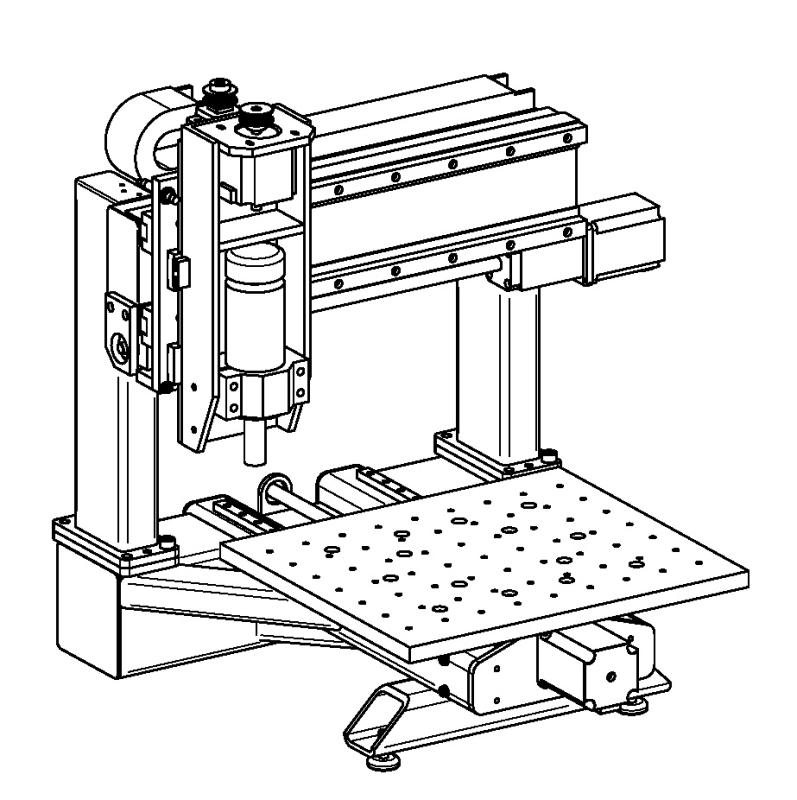

A Local South African company ran into a production issue when their machines’ PC software crashed, leaving them stuck with no means of continuing work. The Pedrazolli Stern 50 is the client’s main use for end tapering on pipes. We were commissioned with the task of re-engineering this ancient, 25-year-old Italian machine.

Applying our previous cost-efficiency strategy, we analysed the existing equipment we would be connecting to. This project only possessed solenoid valves and a couple of sensors that were to be kept. The entire panel, control system, and software were redone from scratch.

The challenge we faced with this machine was integrating third-party motion control devices with the B&R PLC during tool change. The X-Axis, based on hydraulic movement, is controlled via the B&R PLC. The Z and Y-AXIS, based on servo drive motion, are controlled by the Third-Party motion controller.

Control Panel and Pedastal

The client was thrilled with the outcome! They expressed satisfaction with the increased efficiency and precision of the machine. The modernised interface made operation more intuitive, and they appreciated the significant reduction in downtime due to maintenance issues. Overall, they felt that the upgrade not only met but exceeded their expectations, enhancing their production capabilities and providing a competitive edge in their market.

Assessment and Planning:

Hardware Overhaul:

Software Implementation:

Wiring Revamp:

Testing and Calibration: